nano EDGE ENGINE

where innovation

meets simplicity

What is nano EDGE ENGINE?

nano EDGE ENGINE is an embedded software platform dedicated to EDGE Devices with microcontrollers, making them IoT-ready building devices with smart functionalities.

The nano EDGE ENGINE introduces a user-friendly interface that makes working with the device very efficient. It provides a predefined quadruple structure tree of the device, which guides the user through the whole process of setting and working with the device.

nano – extremely light software engine designed to be installed on EDGE Devices based on microcontrollers such as actuators, controllers, I/O modules, sensors, etc.

EDGE – tailored to provide EDGE Devices with intelligent and smart functionalities with secure connectivity to make them EDGE Devices ready for the IoT.

ENGINE – allowing to build logic, integrate with other devices, collect data, expose data and connect with cloud. It’s developed

to be hardware independent.

Clear and logical structure

1.

Applications the functional center of the device. Here are located time-deterministic, cycle-driven multithreaded applications.

It means that they are executed in repeated periods lasting as long as a cycle time is set by the user and they work simultaneously.

2.

Networks peripheral communication center of the device. It includes components that allow the device to transfer the HVAC automation data needed for the device to communicate externally using open communications protocol like Modbus or BACnet.

3.

Services utility center of the device. This part incorporates all services that enhance the basic functionality of the device.

These services involve exchanging information with systems or devices that are higher-level than the building automation level.

They can provide data to algorithms that are typically not available in the building automation system.

4.

System configuration center of the device. It provides the hardware characteristics of the device with information such as device model, version of the operating system, free memory and allows configuring its settings.

Cycle-driven

multithreaded application

Multi-application with different cycles for efficient resources management from fast responding to less demanding applications.

The user may define the application purpose (heating, lighting, etc.) and a cycle time of algorithms operation (cycles may differ between applications).

It will be cycle driven and work simultaneously.

Multithreaded applications allow to differentiate cycles of applications (scan period) in order to adjust them according to a purpose of an application.

Room control application may be set to 1000 ms scan period, and a Lights application to 200 ms scan period, as changes to lights operation have to be implemented immediately. Setting such scan periods would mean that the Lights application would be executed 5 times for each HVAC application cycle.

Data Points with auto

exposition mechanism

It is a mechanism allowing all Data Points added to the project to be exposed to the BACnet or Modbus network by default.

Data Points are fundamental elements that represent a value in the application logic. They can function as setpoints, sensor readings, non-volatile variables, or any other data values.

Data Points represent a layer of the application logic that is accessible to end-users, enabling them to modify setpoints or invoke other actions outlined in the application logic.

Additionally, Data Points can read values calculated in applications and control local or remote outputs.

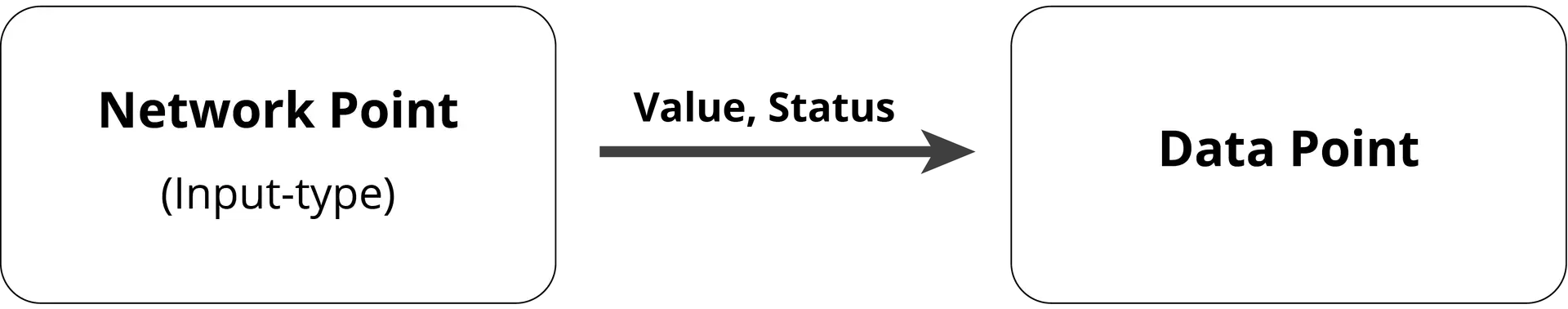

Reference linking method

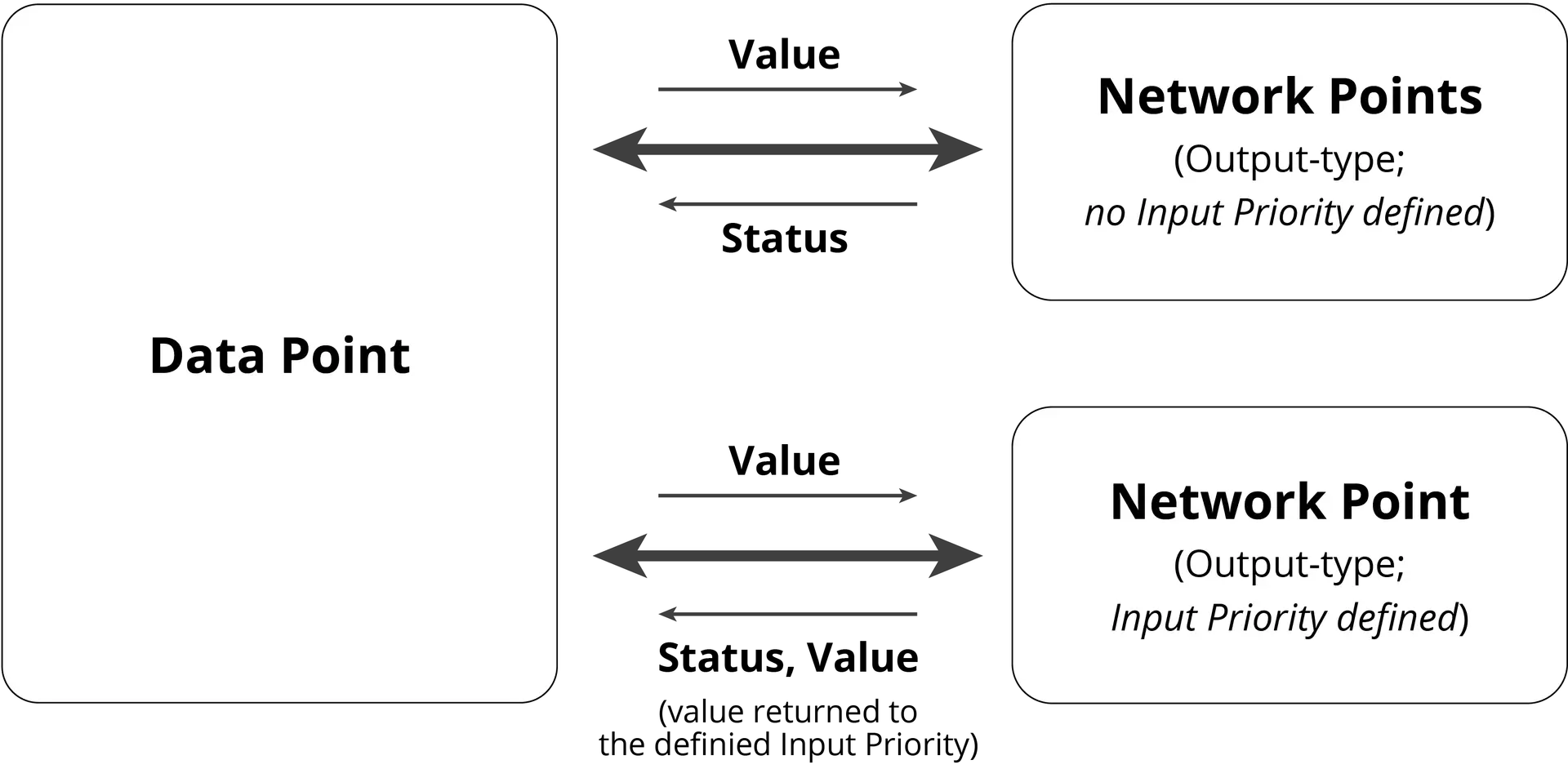

The nano EDGE ENGINE offers an innovative linking method called the Reference link. Is it designed to link Data Points with network points, transferring value along with the component’s status.

The reference link behaves bidirectionally. It transfers the value from the Data Point to the network point, and in turn, it informs whether the value has been correctly received by the network point by sending back the network point’s status.

The reference link method is also able to return its value. The network point’s slot, Input Priority, is designed to identify the Data Point’s priority, which the network point will transfer its value back to.

Libraries

nano EDGE ENGINE is a universal software engine built in a modular way, allowing users to install only the required libraries. This provides flexibility, allowing them to freely decide on the final purpose of the device. Users can choose from a set of components and libraries designed for the building automation sector.

Products

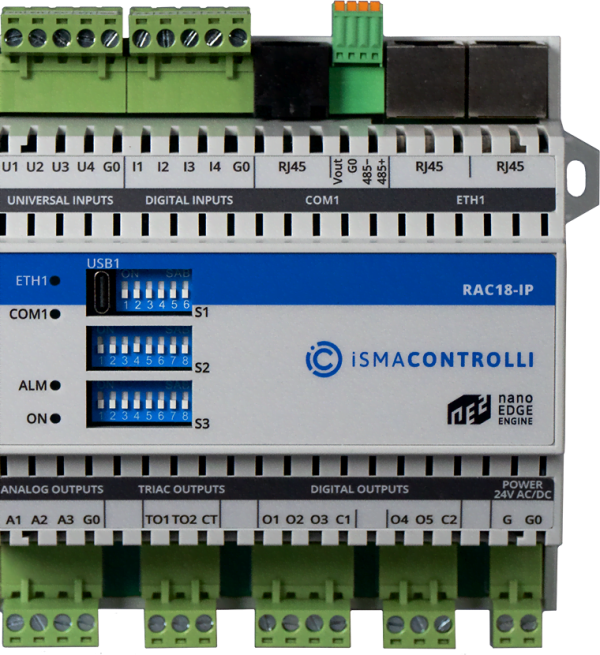

The RAC18-IP controller is a freely programmable multifunctional device providing comfort in a single room or a zone in a building. 18 onboard I/O’s, with Ethernet and serial ports.

High-end Technology at the Edge. Powerful, IoT-ready nano EDGE ENGINE allows unprecedented capabilities for a microcontrollerbased device.

Take advantage of the time-saving automatic BACnet exposure, real-time programming, and cloud connectivity.

The RAC18-IP controller is a multifunctional device providing comfort in a single room or a zone in the building.

Onboard 18 I/O’s with Ethernet and serial ports make the controller a versatile system for comfort management, light and blind control, integration and monitoring.

Tools

1.

System Integrators Native Programming Tool:

Clear and logical programming structure.

Online programming and device management.

Creating numerous independent, cycle-driven user applications.

2.

Innovative Concepts of Intuitive User Interface:

Real-time monitoring of system states, values, and logs.

Provides a set of libraries and components tailored to create cycle-driven user applications.

Network communication based on Data Points provided automatically exposes as a BACnet object merous independent, cycle-driven user applications.

Want to learn more?

iSMA CONTROLLI S.p.A. © 2021 All Rights Reserved. | P.IVA IT01572610994

This site use reCAPTCHA and YouTube API Services. Google Privacy Policy and YouTube Terms of Service apply.