nano EDGE ENGINE

where innovation

meets simplicity

What is nano EDGE ENGINE?

nano EDGE ENGINE is an embedded software platform dedicated to EDGE Devices with microcontrollers, making them IoT-ready building devices with smart functionalities.

The nano EDGE ENGINE introduces a user-friendly interface that makes working with the device very efficient. It provides a predefined quadruple structure tree of the device, which guides the user through the whole process of setting and working with the device.

nano – extremely light software engine designed to be installed on EDGE Devices based on microcontrollers such as actuators, controllers, I/O modules, sensors, etc.

EDGE – tailored to provide EDGE Devices with intelligent and smart functionalities with secure connectivity to make them EDGE Devices ready for the IoT.

ENGINE – allowing to build logic, integrate with other devices, collect data, expose data and connect with cloud. It’s developed

to be hardware independent.

![]()

Applications the functional center of the device. Here are located time-deterministic, cycle-driven multithreaded applications.

It means that they are executed in repeated periods lasting as long as a cycle time is set by the user and they work simultaneously.

Networks peripheral communication center of the device. It includes components that allow the device to transfer the HVAC automation data needed for the device to communicate externally using open communications protocol like Modbus or BACnet.

Services utility center of the device. This part incorporates all services that enhance the basic functionality of the device.

These services involve exchanging information with systems or devices that are higher-level than the building automation level.

They can provide data to algorithms that are typically not available in the building automation system.

System configuration center of the device. It provides the hardware characteristics of the device with information such as device model, version of the operating system, free memory and allows configuring its settings.

The user may define the application purpose (heating, lighting, etc.) and a cycle time of algorithms operation (cycles may differ between applications). It will be cycle driven and work simultaneously.

Multithreaded applications allow to differentiate cycles of applications (scan period) in order to adjust them according to a purpose of an application.

Room control application may be set to 1000 ms scan period, and a Lights application to 200 ms scan period, as changes to lights operation have to be implemented immediately. Setting such scan periods would mean that the Lights application would be executed 5 times for each HVAC application cycle.

It is a mechanism allowing all Data Points added to the project to be exposed to the BACnet or Modbus network by default.

Data Points are fundamental elements that represent a value in the application logic. They can function as setpoints, sensor readings, non-volatile variables, or any other data values.

Data Points represent a layer of the application logic that is accessible to end-users, enabling them to modify setpoints or invoke other actions outlined in the application logic.

Additionally, Data Points can read values calculated in applications and control local or remote outputs.

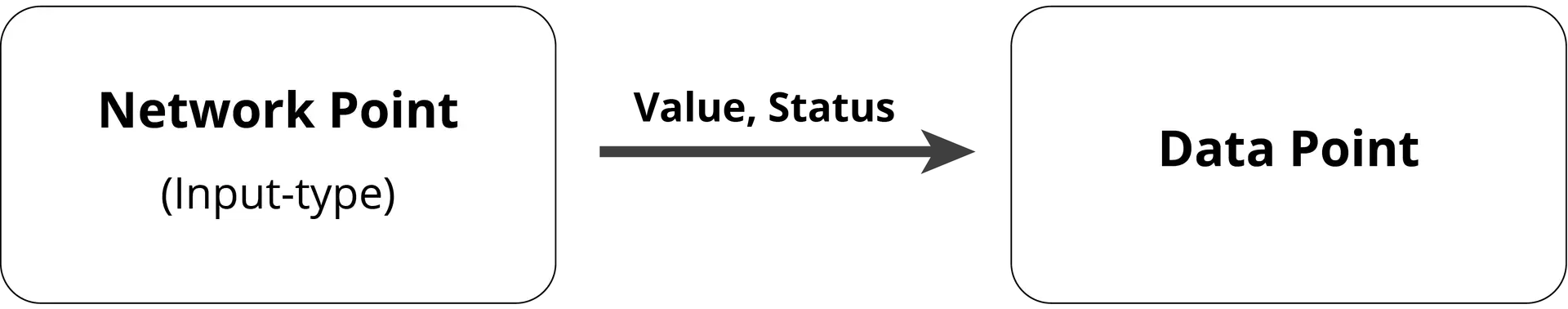

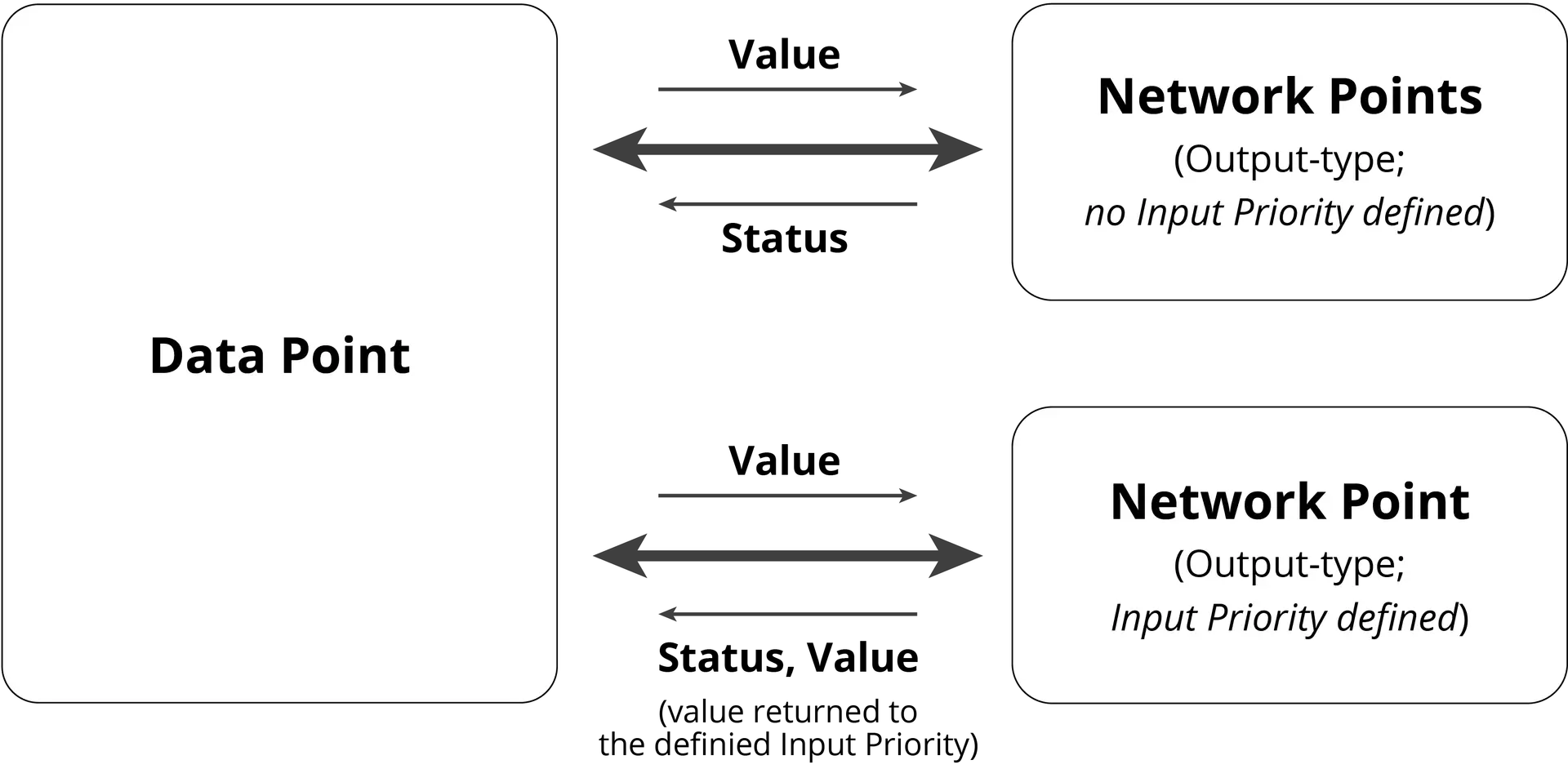

The nano EDGE ENGINE offers an innovative linking method called the Reference link. Is it designed to link Data Points with network points, transferring value along with the component’s status.

The reference link behaves bidirectionally. It transfers the value from the Data Point to the network point, and in turn, it informs whether the value has been correctly received by the network point by sending back the network point’s status.

The reference link method is also able to return its value. The network point’s slot, Input Priority, is designed to identify the Data Point’s priority, which the network point will transfer its value back to.

Libraries

nano EDGE ENGINE is a universal software engine built in a modular way, allowing users to install only the required libraries. This provides flexibility, allowing them to freely decide on the final purpose of the device. Users can choose from a set of components and libraries designed for the building automation sector.

OS

OS

Backup & Restore

The Backups component allows to perform and restore backups.

Library Core

Library Core

DHCP

nano EDGE ENGINE devices are able to received automatic IP address settings from the available DHCP server.

DNS

Component allows to automatically obtain the addresses of DNS servers.

Library Schedules

Library Schedules

Special Events & Calendar, Schedules.

Functionality allow to set values in a logic according to schedules depending on calendar time.

Library Time

Library Time

NTP Client

Using the Network Time Protocol, the devices can have precise time configurations across the whole BMS network.

Library Math

Library Math

Includes components representing mathematical operations essential for creating logics.

Library FCU

Library FCU

Contains components to create FCU applications like: Fan Control, Occupany Calculator, PWM, Temperature sensors and Mode Calculator.

Library Logic

Library Logic

Contains components representing logical operations essential for creating applications, such as conjunction, alternative denial, joint denial, disjunction, or simple comparisons and more.

Library Process

Library Process

Includes components essential to represent processes, which can be applied to HVAC management or other uses, like Curve, Hysteresis, Latch, Loop, Thermostat etc.

Library IO

Library IO

Consists of network point components, dedicated to read and control the inputs and outputs of the actual device. They are defined for various type of physical inputs and outputs.

Library BACnet

Library BACnet

MS/TP Client,

MS/TP Server,

IP Client, IP Server

It allows the device to be recognized and identified in the BACnet network as a BACnet device, and to handle an incoming BACnet communication as client and server device.

Library Modbus

Library Modbus

RTU Client, RTU Server,

TCP/IP Client, TCP/IP Server, Modbus TCP/IP to RTU Gateway

It allows the device to be recognized and identified in the Modbus TCP/IP network as a Modbus server device, and to work as a Modbus RTU or TCP/IP client device.

Library Other

Library Other

The Other library is designed for components that can facilitate operating of an application or that fulfill the roles, which are not met by any other thematic libraries.

Library VAV

Library VAV

Components dedicated to VAV control, like Air Flow Calculator, Damper Control, Heat and Cool control.

Library Comfort Control

Library Comfort Control

Advanced components to manage and control comfort to determines the occupancy status and temperature source based on multiple inputs( network, window contact, presence detector etc.)

Under development

Funtions to record changes in value of a property, locally within the physical BACnet device

The visualization web server allows to present basic information about an application controlled by nano EDGE ENGINE controllers.

Library enabling communication on the DALI2 bus, supporting Control Gears and Input Devices. Supported up to 128 devices on bus. Components for lighting control.

Alarms will be tightly connected to Data Points as we are interested in their value.

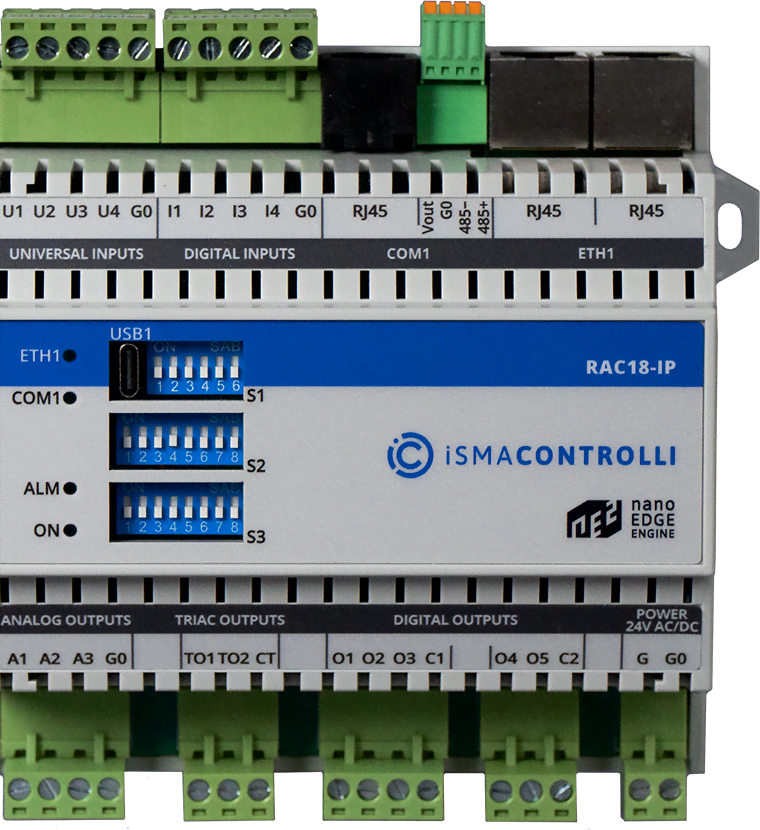

RAC18-IP

Niagara Enabled Room Application Controller

The RAC18-IP is a freely programmable, Niagara enabled controller equipped with 18 I/Os, ideal for room, zone and light HVAC applications.

Future-proof Architecture.

Suitable for infrastructure of new buildings with native support for IP communication with BACnet and Modbus protocols. The fail-safe Ethernet switch ensures IP communication continuity even in case of a power failure.

Seamless programming and integration.

The USB-C port facilitates local programming and allows the controller to be powered from a computer. RAC18-IP supports real-time programming over IP using free of charge iC Tool or with a dedicated Niagara Framework® extension.

On-board RS485 port with spring terminal and smart plug for seamless connection of iSMA CONTROLLI wall panels or integration of any BACnet/Modbus device on a serial bus.

VAV14-IP

Niagara Enabled VAV Controller

Unique 2-in-1.

Configurable and freely programmable VAV controller with built-in damper actuator and differential pressure sensor. Fail-safe Ethernet port, quick-connector socket for wall panels and 13 I/Os makes it versatile controller for variety of applications.

Ultimate flexibility in the VAV control.

VAV14-IP solves the complexity of advanced VAV systems and their integration with building management technologies, with its unique configuration and commissioning flexibility. For custom applications, it is also possible to change the algorithm or program the controller from scratch using Niagara Framework or free-of-charge iC Tool.

Efficient application for VAV boxes.

To minimize time and simplify the commissioning process, the VAV14-IP Controller is equipped with a pre-loaded application, which supports the most popular types of VAV boxes.

Various ways of commissioning the VAV system.

iSMA CONTROLLI provides installers, system integrators, and programmers with unique tools and software for configuring, commissioning, balancing and programming the VAV14-IP Controller.

What are we working on?

Upcoming products with built-in

nano EDGE ENGINE

operating system.

UAC28-IP

Unitary Application Controller

USB type C

2x Ethernet port with built-in switch

1xRS485

Built-in webserver

ZAC24-IP

ZAC24-IP

USB type C 2x Ethernet port with built-in switch

1xRS485

DALI 2 interface

Built-in webserver

Preloaded application for Zone Management control

Tools

1.

System Integrators Native Programming Tool:

Clear and logical programming structure.

Online programming and device management.

Creating numerous independent, cycle-driven user applications.

2.

Innovative Concepts of Intuitive User Interface:

Real-time monitoring of system states, values, and logs.

Provides a set of libraries and components tailored to create cycle-driven user applications.

Network communication based on Data Points provided automatically exposes as a BACnet object merous independent, cycle-driven user applications.

Want to learn more?

Sign up

Register to our mailing base to receive more information about the upcoming products.

Copyright (C) 2025 iSMA CONTROLLI. All rights reserved.

Copyright (C) 2025 iSMA CONTROLLI. All rights reserved.

Main Office:

iSMA CONTROLLI

Via Carlo Levi, 52Sant’Olcese,

GE 16010 Italy

Full Contact Details >>